Handling & Cleaning Coated Optical Components

Leave a CommentThe following recommendations are made as an aid to our customers who may not be familiar with the proper handling of coated optical components. Please contact your ECI sales representative if you require further assistance.

HANDLING

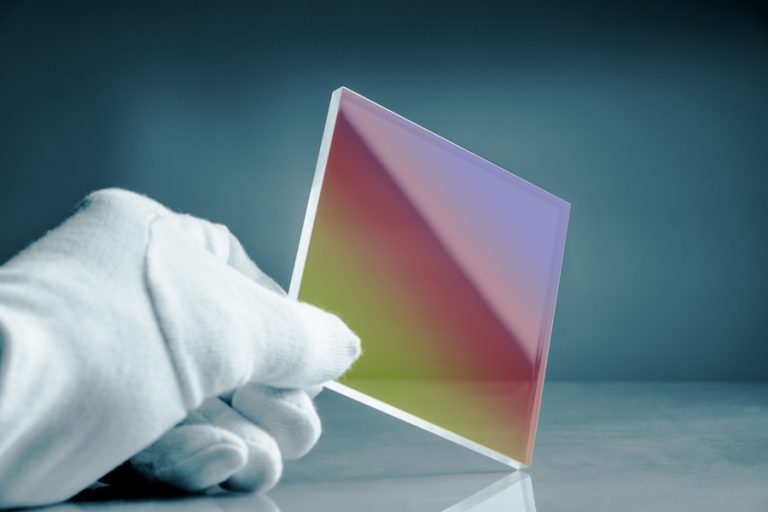

- Coated optical elements should be handled by trained personnel only. Avoid touching coated surfaces. Hold elements with clean gloves or finger cots by edges or uncoated areas.

- Do not allow optical elements to come in contact with each other. The element and/or coating may become scratched.

- When not in use, coated elements should be wrapped in lens tissue or stored in a closed container.

CLEANING

- If it’s not dirty, don’t clean it!!!

If cleaning of the coating becomes necessary, please follow this procedure:

- Dust off the optical element using a canned clean air duster, compressed/filtered air, or nitrogen before wiping any optic.

- Moisten a lint free lens tissue, cotton swab/cotton ball, or soft clean cloth with solvent. We recommend:

For Glass

- Acetone

- Methanol (Mixture of 60% Acetone/40% Methanol) preferred

For many Plastic

- 50/50 mix of Isopropyl Alcohol and Deionized water.

These solvents (or other organic solvents) will not damage the optical coating. Please consult the manufacturer of the optical element if unsure of the solvent’s effect on the element.

- Drag (trail wipe) the moistened wiper gently linearly across the coated surface. Do not rub.

- Repeat this procedure until no contaminants remain.

Please contact ECI for specific recommendations for your parts if necessary.