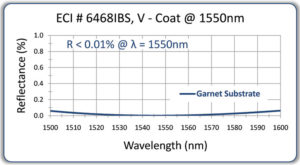

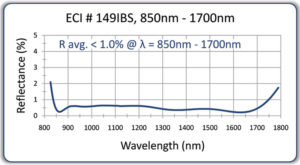

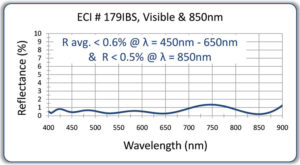

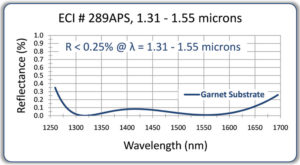

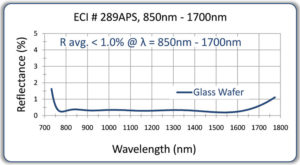

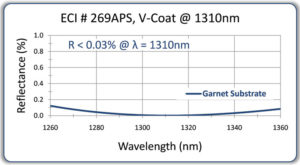

These IBS coating processes exceed the performance of conventional deposition techniques. Coatings are deposited with high energy that produces films with densely packed surface structures, low optical loss, and superior surface qualities. IBS AR coatings also exhibit high laser damage thresholds. Typical results can be > 40J/cm^2 for a pulsed laser @ 1064nm and > 1GW/cm^2 for a CW laser @ 1064nm. One of the many benefits of IBS AR Coatings is reduced sensitivity to moisture that results in little or no spectral shift. Designs are available for deposition on many types of substrate materials including.

- LiNbO3

- LiTaO3

- KTP

- LBO

- YAG

- TGG

- Silicon

- InP

- Garnet

- Ultra Thin Wafers

ECI has developed many innovative methods for fixturing your ultra thin wafers, crystals and semiconductor materials. Our highly experienced production team has the skills and commitment to quality to handle your sensitive materials.

ECI also designs high performance AR coatings that withstand your required laser damage thresholds.

Contact our design team to discuss your specific AR Coatings for Crystals and Semiconductor Materials application!