A Brief Guide to Thin-Film Optical Filters

Leave a CommentWhat Are Thin-Film Optical Filters?

Thin-film optical filters are optical devices consisting of alternating thin layers of specialized optical coatings deposited onto a substrate (e.g., optical glass). The coating layers alter the refractive index of the substrate, changing the direction of the various wavelengths in incoming light as it passes through one layer to the next. Either reflection, transmission, or absorption can occur depending on the wavelength(s) of the incoming light and the type of optical filter employed.

Types of Thin-Film Optical Filters

Thin-film optical filters are suitable for use with light in the ultraviolet (UV) to infrared (IR) wavelength range. They can be classified into five basic categories based on their spectral shape: bandpass filters, notch filters, shortpass edge filters, longpass edge filters, and dichroic filters. For more information on the various types available, check out this thin-film optical filter blog post.

Applications of Thin-Film Optical Filters

Thin-film optical filters are highly customizable, which allows them to be designed and built for effective performance in extremely specific or unique light-based applications. They are used across a wide range of industries in a variety of devices, equipment, and systems for many different use cases, including, but not limited to, the following:

- Biological image detection. They can filter luminescence to facilitate the operation of biological imaging devices.

- Chemical analysis. They can isolate specific emission or absorption ranges from incoming light to aid in chemical identification and analysis operations.

- Contrast enhancement. They can increase the contrast between objects during scanning and other imaging operations to improve identification, recognition, and verification.

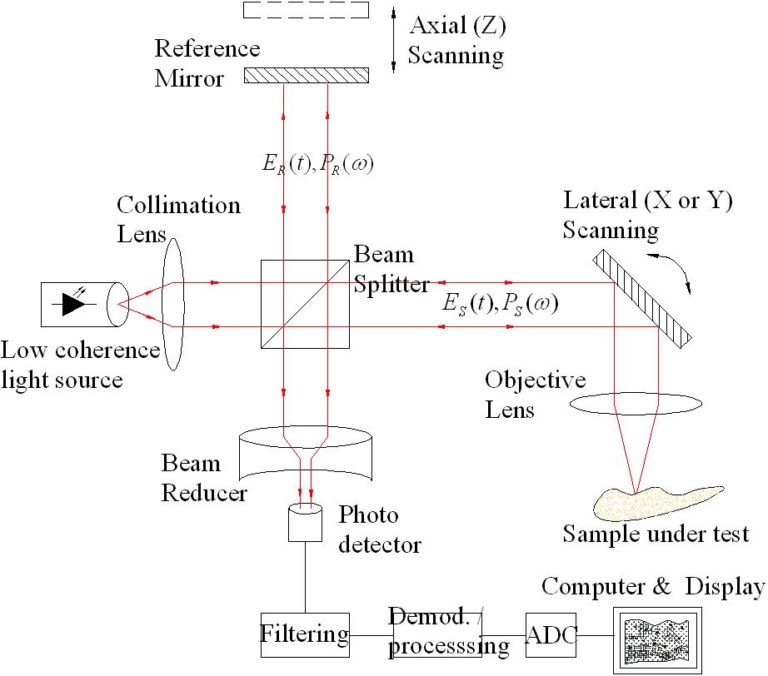

- Laser systems. They can manipulate the beam of light generated in laser systems.

- They can separate and modify signal transmissions in telecommunication systems.

- Visible light coloring. They can add or enhance the hue of visible light to achieve a specific aesthetic effect.

Thin-Film Optical Filter Solutions From Evaporated Coatings, Inc.

Thin-film optical filters find use in a variety of light transmission, blocking, and absorption applications. As their design and construction—i.e., the optical substrate and coating used—vary depending the application, some customers may find it challenging to select and source a product that meets their needs. Fortunately, the experts at Evaporated Coatings are here to help.

At Evaporated Coatings, Inc., we specialize in the supply of high-precision optical coatings. Equipped with over 60 years of industry experience, we can help customers select the right coating and apply it to their substrates. Visit our custom optical filter page to learn more about our thin-film coating capabilities. If you want to discuss your optical filter requirements with one of our experts, contact us today.