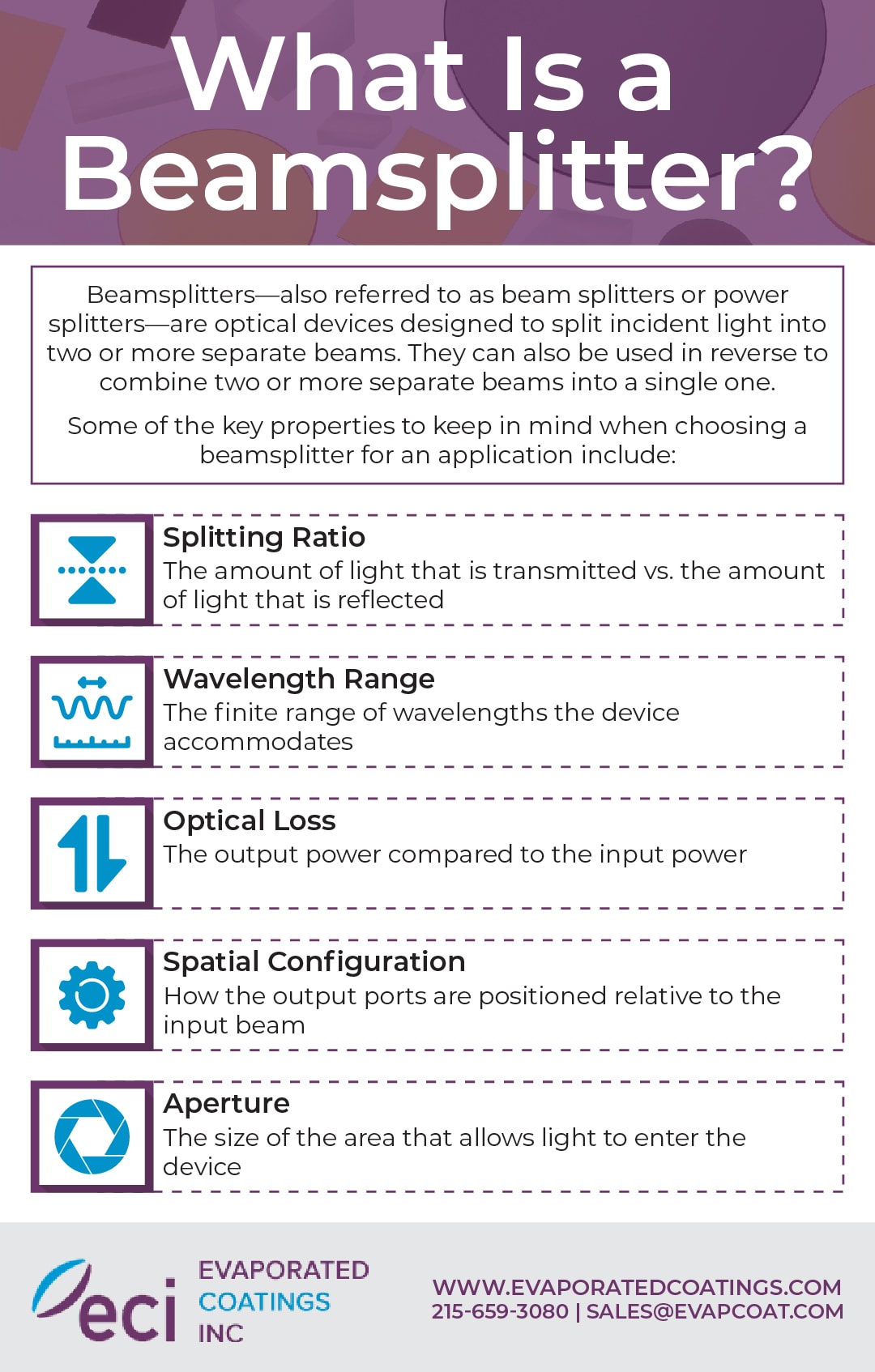

What Is a Beamsplitter?

Beamsplitters—also referred to as beam splitters or power splitters—are optical devices designed to split incident light into two or more separate beams. They can also be used in reverse to combine two or more separate beams into a single one.

Some of the key properties to keep in mind when choosing a beamsplitter for an application include:

- Splitting ratio: the amount of light that is transmitted vs. the amount of light that is reflected

- Wavelength range: the finite range of wavelengths the device accommodates

- Optical loss: the output power compared to the input power

- Spatial configuration: how the output ports are positioned relative to the input beam

- Aperture: the size of the area that allows light to enter the device

How Does a Beamsplitter Work?

As indicated above, beamsplitters are used to split incident light into two or more separate beams. The splitting process is dependent on the wavelength, intensity, or polarity of the incoming light and the design and configuration of the beamsplitter. Regardless of these factors, however, all beamsplitters follow the same basic principles: incoming light is split into two or more beams with one or more continuing forward through the optical component (i.e., transmitted) and one or more directed at an angle out of the optical component (i.e., reflected).

Due to their ability to split light into separate beams based on controlled reflected/transmitted (R/T) ratios, beamsplitters find use in a wide range of light-based devices and equipment, including, but not limited to, the following:

- Cameras and projectors

- Fiberoptic systems

- Head-up displays (HUDs)

- Laser alignment and attenuation systems

- Medical imaging systems

- Sensors

Types of Beamsplitters

While all beamsplitters perform the same basic function—i.e., splitting light into separate beams—how they do so varies depending on their design. For example:

- Standard beamsplitters split incident light without regard to the wavelength, polarization state, or intensity. They are generally used for one-way mirrors and illuminating assemblies and subassemblies.

- Dichroic beamsplitters split incident light by wavelength. They are typically employed as laser beam combiners or broadband hot/cold mirrors.

- Polarizing beamsplitters split incident light by polarization state. They are ideal for use in photonic instrumentation systems.

- Non-polarizing beamsplitters split incident light by intensity. They are suitable for applications that utilize polarized light.

Standard, dichroic, polarizing, and non-polarizing beamsplitters are available in a variety of configurations. Some of the most common include:

- Cube beamsplitters. Cube beamsplitters consist of two right-angle prisms connected at the hypotenuse with a semi-reflective coating at the point of connection. They are suitable for applications that require simple mounting mechanisms and durable optical components.

- Plate beamsplitters. Plate beamsplitters are made from flat and thin glass plate with a special coating on the first surface of the substrate. They are typically used for light with a 45-degree angle of incidence and can be built to support multiple incident ratios.

- Pellicle beamsplitters. Pellicle beamsplitters are made from very thin substrates. This design allows for minimal beam offset.

- Polka dot beamsplitters. Polka dot beamsplitters feature a pattern of reflecting dots on the glass surface. This design allows for geometrical beam splitting that is not angle-dependent.

Custom Beamsplitter Coating Solutions From Evaporated Coatings, Inc.

Beamsplitters serve a critical function in a wide range of light-based applications. Ensuring they operate as intended necessitates verifying the base substrate has the proper mechanical properties and utilizing the right optical coating. If you’re looking for an experienced and knowledgeable supplier for your beamsplitter coating needs, turn to the experts at ECI.

At Evaporated Coatings, Inc. (ECI), we’ve supplied high-precision optical coatings for over 50 years. This extensive experience allows us to manufacture beamsplitter coatings for a wide range of R/T ratios, wavelength ranges, angles of incidence, polarization states, incident mediums, and temperature sensitivities and apply them to various customer-supplied substrates (e.g., glass, plastic, molded polymer, semiconductor materials, fibers, and fiber optic devices).

Visit our beamsplitter page to learn more about our beamsplitter coating solutions. To discuss your beamsplitter requirements with one of our experts, contact us today.