One of the many benefits is stable optical thin films with little or no spectral shift due to reduced coating sensitivity to high humidity and varying temperature conditions.

Our in-house design team will work closely with you to design a custom laser mirror coating that meets your performance objectives. Typical designs provide up to 99.95%* reflection over your specified wavelength region.

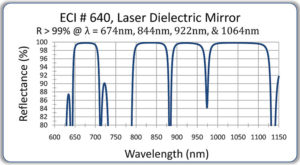

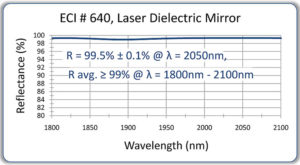

Designs can be optimized for use from 248nm – 2500nm for laser line wavelengths or multi band applications that require excellent environmental stability.

ECI’s custom laser mirror coatings are designed to ensure maximum performance for your systems. Specify your particular wavelength range, angle of incidence, substrate index of refraction, incident medium and polarization for the optimum coating performance. Coatings are available for direct deposition onto: glass, wafers, fiberoptic devices, and semiconductor materials.

ECI also manufactures Laser Dielectric Mirror Coatings for high power applications that require coatings with significant laser damage thresholds. ECI’s design team will recommend the optimum coating for your high power laser application!

ECI’s Laser Dielectric Mirror coatings meet environmental and durability requirements of MIL-C-48497; Laser Dielectric mirror coatings on glass and other substrates that withstand elevated temperatures meet the environmental and durability requirements of MIL-F-48616.

*Reflection levels are dependent on composition of optical component.

EXAMPLES OF LDT

High Laser Damage Threshold Highly Reflective & Filter Coatings

| Wavelength | LDT* | Pulse width |

|---|---|---|

| 355 nm | 2 J/cm2 | 20 ns |

| 532 nm | 6 J/cm2 | 20 ns |

| 1030 nm | 0.47 J/cm2 | 319 fs |

| 1064 nm | 40 J/cm2 | 20 ns |

Contact our design team to discuss your specific Laser Dielectric Mirror Coatings application!