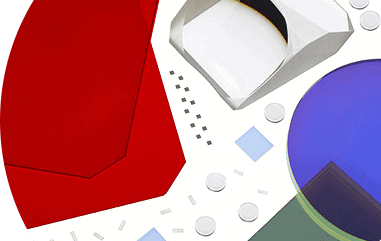

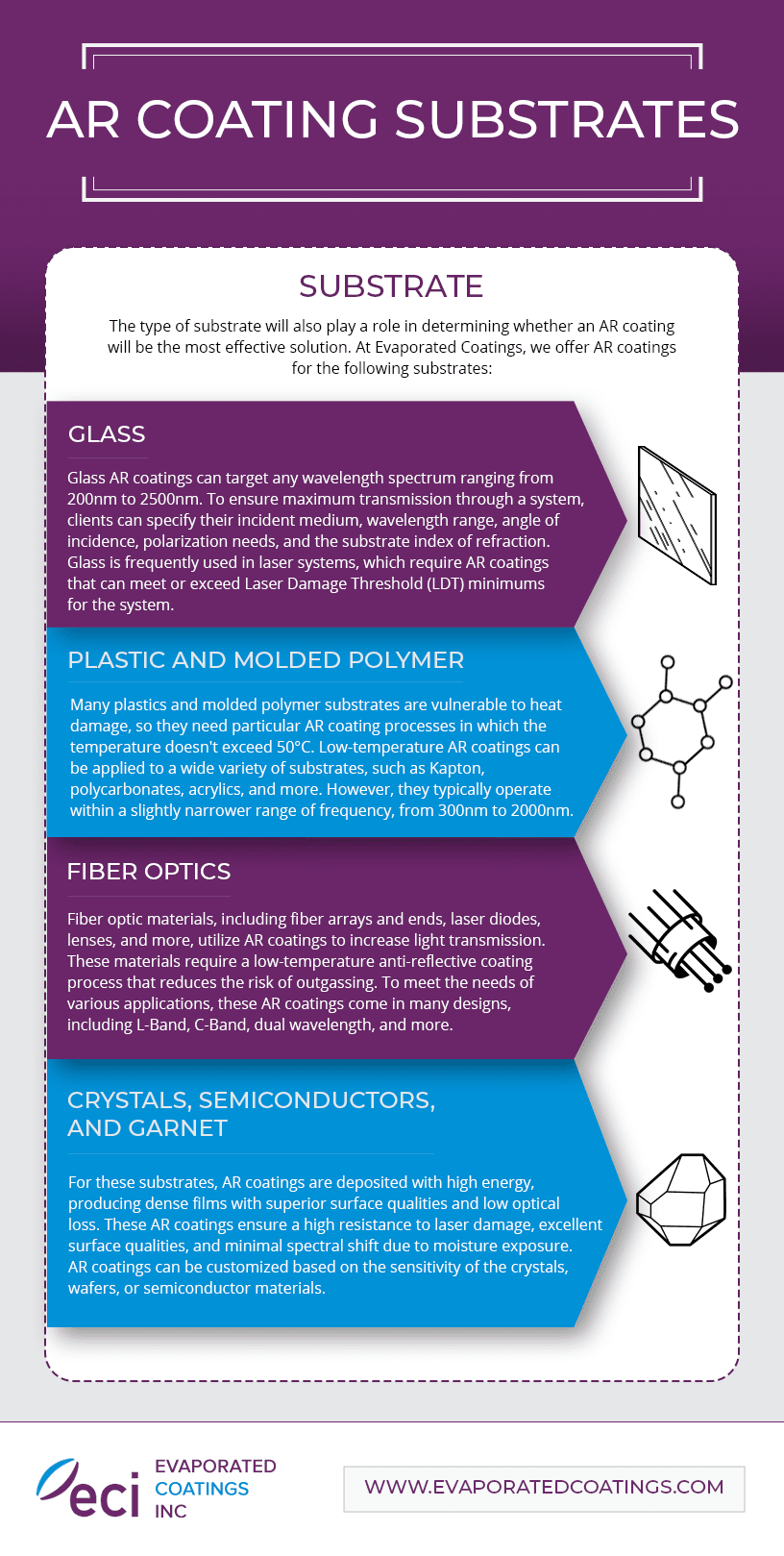

AR Coating Substrates

The type of substrate plays a critical role in determining whether an Anti-Reflective (AR) coating will be an effective solution. At Evaporated Coatings, we offer AR coatings for a variety of substrates.

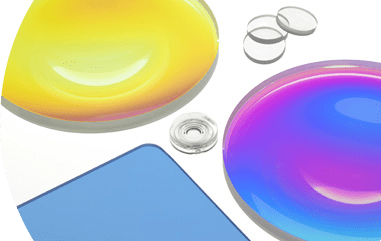

Glass

Glass AR coatings can target any wavelength spectrum ranging from 200nm to 2500nm. To ensure maximum transmission through a system, clients can specify their incident medium, wavelength range, angle of incidence polarization needs and the substrate index of refraction. Glass is frequently used in laser systems, which require AR coatings that can meet or exceed Laser Damage Threshold (LDT) minimums for the svstem.

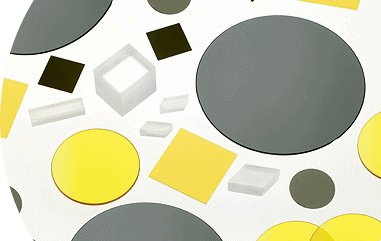

Plastic and Molded Polymer

Many plastics and molded polymer substrates are vulnerable to heat damage, so they need particular AR coating processes in which the temperature doesn’t exceed 50°C. Low-temperature AR coatings can be applied to a wide variety of substrates, such as Kapton, polycarbonates, acrylics, and more. However, they typically operate within a slightly narrower range of frequency, from 300nm to 2000nm.

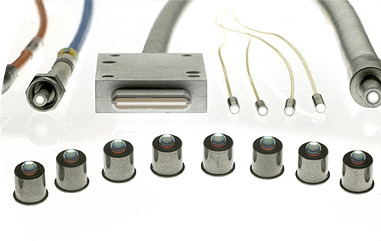

Fiber Optics

Fiber optic materials, including fiber arrays and ends, laser diodes, lenses, and more, utilize AR coatings to increase light transmission. These materials require a low-temperature anti-reflective coating process that reduces the risk of outgassing. To meet the needs of various applications, these AR coatings come in many designs, including L-Band, C-Band, dual wavelength, and more.

Crystals, Semiconductors, and Garnet

For these substrates, AR coatings are deposited with high energy, producing dense films with superior surface qualities and low optical loss. These AR coatings ensure a high resistance to laser damage, excellent surface qualities, and minimal spectral shift due to moisture exposure. AR coatings can be customized based on the sensitivity of the crystals wafers or semiconductor materials.

Metal Mirror Coating Substrates

Evaporated Coatings also offers protected and enhanced metal mirror coatings for glass and metal substrates. Our metal mirror coatings are made from gold, silver and aluminum and are optimized for UV-to-infrared wavelengths. They also meet the environmental and durability requirements of MIL-M-13508C.