Polarization in Optics

Polarized light is critical for a wide variety of optical applications. While optical equipment is often designed to modify light intensity and wavelengths, polarization offers its own set of unique benefits and properties. It helps to filter light to specific wavelengths, enhance laser beams, and reduce the effects of reflection and refraction of light waves.

Polarization is used to perform material stress testing and conduct scatter analysis of biological, chemical, and pharmaceutical samples. The polarization of light is also responsible for the effects of 3D glasses and glare-reducing eyewear and can be used to provide clarity in photography, microscopy, and telescopy.

What is Polarization?

Light consists of both electrical and magnetic energy, and is therefore an electromagnetic wave. It is also a transverse wave, which means that the light’s electric field oscillates at a right angle to the axis along which the light travels. If the oscillation is random, the light is scattered in many directions. This is the primary difference between polarized vs unpolarized light. Unpolarized light can be seen coming from common light sources, such as light bulbs and the sun. Polarization narrows the field of light by limiting the angles at which the light reaches the viewer or sensor, reducing scatter and reflection. This process is most evident in lasers, which consist of one directed beam of light energy.

Light consists of both electrical and magnetic energy, and is therefore an electromagnetic wave. It is also a transverse wave, which means that the light’s electric field oscillates at a right angle to the axis along which the light travels. If the oscillation is random, the light is scattered in many directions. This is the primary difference between polarized vs unpolarized light. Unpolarized light can be seen coming from common light sources, such as light bulbs and the sun. Polarization narrows the field of light by limiting the angles at which the light reaches the viewer or sensor, reducing scatter and reflection. This process is most evident in lasers, which consist of one directed beam of light energy.

What is Polarization Control?

Polarization control refers to the methods used to ensure optimal polarization in optical operations. Manufacturers and operators of optical equipment modify the reflectivity, beamsplitter ratios, and insertion loss based on the desired polarization. Using a variety of methods, users modify the direction and flow of light waves to reduce glare and eliminate energy outside the desired range. The result is targeted light that produces superior imaging, color, and contrast without interference.

Not only does polarization block unwanted energy for visual applications like cameras and microscopes, but it can also be used to detect material properties by measuring the changes in light waves when they interact with a sample. By evaluating the fine changes in light polarization from reflected and transmitted light, users can determine the chemical, magnetic, mechanical, and other properties of the material.

Each of these operations requires extreme precision to ensure optimal performance and reliable results. To meet specific needs for polarization in a variety of applications, many polarizing methods have been developed. Each method uses particular materials that control the flow and direction of light beams through the use of absorption, transmission, or reflection.

The Role of Polarizers and Waveplates

Unpolarized light consists of waves of light that oscillate at random, transmitting light along multiple axes. Polarizers and waveplates filter, redirect, or otherwise modify the light waves to eliminate light that is not moving along the desired axis. Polarization typically isolates waves that either run parallel or perpendicular to the axis of the light’s linear motion.

Polarizers

Polarizers are optical components that only transmit light waves along an axis relative to the light’s incident polarization. In essence, they allow the flow of light to move through the polarizer along the desired axis while rejecting the light moving along other axes. Polarizers can be divided into three categories based on the way they filter light:

- Reflective polarizers transmit the desired polarization while reflecting the light waves on the other axes.

- Dichroic polarizers absorb light along a specific polarization, allowing the remaining light to be transmitted.

- Birefringent polarizers refract light from different polarizations, which allows users to select which polarizations they require based on the refraction index of the light waves.

Waveplates

Unlike polarizers, which simply filter out undesired polarizations, waveplates modify the flow of light without reducing, displacing, or deviating the beam. Instead, they convert the flow of polarization into a new state by modifying the speed of certain polarizations. To modify the light at different polarizations, waveplates are composed of materials with a structured crystal lattice, such as quartz or calcite. The plate is cut at an angle in relation to the crystalline structure that allows users to modify the velocity and refraction of certain polarizations. This converts the orientation of the polarized light from linear to circular or vice versa.

Linear Polarization vs. Circular Polarization

Polarized light is divided into three different polarization classes, based on the orientation of the electric field:

- Linear Polarization. Linear polarization transmits light along a single plane parallel to the direction of flow from the source.

- Circular Polarization. Circular polarization occurs when two perpendicular flows of light of equal strength are directed toward each other with a phase difference of π/2. The relative flow of light from both directions causes it to rotate around the lateral axis of the flow of light from the source.

- Elliptical Polarization. A type of circular polarization, elliptical polarization occurs when the relative flow of light between two linear components has a phase difference other than π/2 or the strength of the flows is unequal. The resultant rotation is elliptical rather than circular.

Polarization in Optical Applications

Polarization is used to facilitate a wide range of optical applications to reduce glare and reflections, eliminate interference from scattered light, and enhance color and light contrasts. It is also critical for optics in analytical applications such as stress detection, chemical and molecular analysis, and microscopic specimen identification and photography.

- Reduce Reflections and Glare. For photography and other imaging applications, scattered light situated between the object and camera can obstruct the view and compromise the resultant image. Polarizers work to reduce glare by preventing or reducing the interference of light outside the desired polarization.

- Enhance Color and Contrast. Light is easily scattered by the electrons present in the atmosphere, which can create washed-out colors and insufficient contrast in photographs. In addition, reflected sunlight from objects can distort and obscure images. Polarized filters in camera lenses reduce the interference from scattered and reflected light, increasing image contrast, focus, and color.

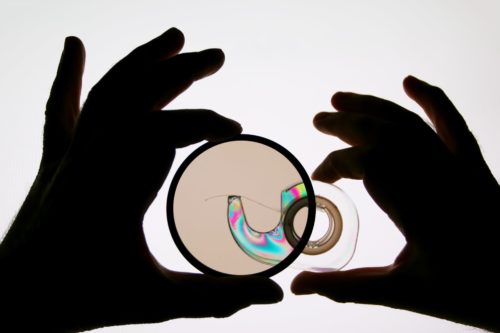

- Stress Detection and Analysis. Different levels of stress within amorphous solids can create slight differences in polarization. By analyzing these variations, users can detect stress levels in a variety of materials and products.

- Chemical and Molecular Identification. Polarization control is vital for geological, chemical, pharmaceutical, oil and gas, and food and beverage applications. Molecules in most samples are grouped into arrangements called stereoisomers. Stereoisomers rotate polarized light in different ways, depending on the molecular make-up and concentration. Using this knowledge, manufacturers can analyze the polarized light rotation to deduce the type and concentration of molecules in a given sample.

- Polarized Light Microscopy. Polarized light microscopy is used to observe and photograph microscopic specimens that have unusual or irregular geometries. Using polarized light, scientists can also detect the movement and direction of specimens.

Superior Optical Coatings by the Experts at Evaporated Coatings, Inc.

Whether you are using polarized optics to enhance your nature photography or to complete detailed imaging of microscopic organisms, Evaporated Coatings, Inc. has the perfect optical coating for your needs. With more than 60 years of experience in the optical coating industry, we understand the need for the utmost precision and clarity in optics applications. We are committed to providing our customers with outstanding optical component coatings for even the most complex systems. Each of our optical coatings is skillfully applied to facilitate and enhance the optical properties of components to ensure optimal light transmission, reflection, and polarization. Our coatings can be added to a variety of substrates, from glass and polymer to semiconductors and fiber optics.

Evaporated Coatings Inc. is an industry leader in the development of optical coatings for a wide range of applications. Our comprehensive selection of optical coatings include:

- Anti-Reflection Coatings

- Ion Beam Sputtering (IBS) Coatings

- Mirror Coatings

- Transparent Conductive Coatings

- Beam Splitters

- Attenuation Coatings

- Metal & Dielectric Depositions

- Custom Coatings

To learn more about ways that our premium coatings can be used in your polarization and other optical operations, contact us today or request a quote for your next project.