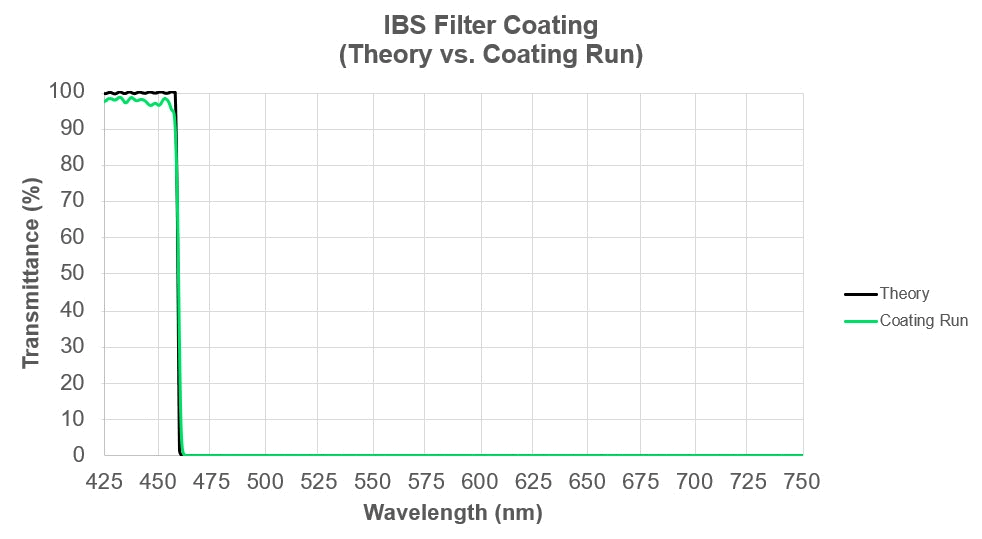

ECI produces thin-film coatings using a variety of different deposition methods, our most advanced deposition method is Ion Beam Sputtering (IBS). Ion Beam Sputtering produces coatings that are very dense with low surface roughness. Another advantage of IBS thin-film coatings is that they exhibit superior thermal stability. IBS coatings can withstand exposure to temperatures up to 300°C for long-term exposure and 500°C for short-term exposure. IBS coatings also exhibit lower thermal shift than other types of coatings. Typically thermal shift is < 0.5pm/°C for Ion Beam Sputtered coatings. Evaporated Coatings’ four IBS coating chambers utilize state of the art monitoring techniques to produce coatings that yield near theoretical performance. Figure 1 shows the actual performance of a filter coating when compared to the theoretical design.

Figure 1: IBS Filter Coating: Theory vs. Coating Run

ECI uses Ion Beam Sputtering to produce many different types of coatings including:

AR (Antireflective) Coatings

AR coatings are designed to utilize destructive interference to reduce Fresnel reflections produced when light passes between two mediums of different index. AR coatings can be optimized for narrowband, broadband or multiband applications.

Dielectric Mirror Coatings

Dielectric Mirror coatings utilize constructive interference to create reflectivity over a given wavelength region. Dielectric mirror coating can be optimized for narrowband, broadband and multiband applications.

Shortwave Pass Filter Coatings

Shortwave Pass Filters are designed to reject, or block, longer wavelength regions and allow shorter wavelength regions to pass through.

Longwave Pass Filter Coatings

Longwave Pass Filters are designed to reject, or block, shorter wavelength regions and allow longer wavelength regions to pass through.

Bandpass Filter Coatings

Bandpass Optical Filters are designed to pass a certain wavelength range, which block both longer and shorter wavelengths. Bandpass filters can be designs for both narrow and wide passbands.

Dichroic Filter Coatings

Dichroic Filters are designed to separate out two discrete wavelength regions. These types of filters are typically either shortwave pass or longwave pass filters that are oriented at non-normal incidence, usually 45°.

Dielectric Beamsplitter Coatings

Dielectric Beamsplitters are designed to partially reflect and transmit light with a specific ratio over a given wavlelength region. Dielectric beamsplitters can be designed for narrowband and broadband applications.

Notch Filter Coatings

Notch Filters are designed to reject a certain wavelength region while allowing both longer and shorter wavelength regions to pass through. Notch filters can be viewed as the inverse of bandpass filters. ECI deposits Notch Filters for narrowband, broadband, and multiband applications.

ECI deposits IBS coatings on several different types of substrates, including:

-

Glass windows and lenses

-

Polymer windows and lenses

-

Glass, Fused Silica and Semiconductor wafers

-

Fiberoptic Components

-

Laser Crystals (LBO, KTP, TGG, BIG, GGG, LiNbO3)

-

Thin glass (< 0.1mm thick)

Applications for Ion Beam Sputtering (IBS) Coatings

Applications for Ion Beam Sputtering (IBS) Coatings

High Power Laser Applications

The high density and low loss exhibited by Ion Beam Sputtering coatings, make them perfectly suited for laser optics and applications. ECI can deposit AR coatings with reflection of less than 0.03%. ECI can also deposit dielectric mirror coatings with reflection greater than 99.9%, which exhibition absorption and scatter loss of less than 10ppm. Evaporated Coatings’ IBS coatings for laser applications perform very well when used with high power lasers. ECI has deposited IBS AR coating that can withstand greater than 40J/cm^2 for a 10ns pulse width at 1064nm and 2GW/cm^2 for continuous wave at 1064nm. ECI has deposited dielectric mirror coatings that can withstand greater than 60J/cm^2 for a 10ns pulse width at 1064nm. While these coatings can be deposited on a variety of different substrates, laser damage threshold will depend on the type and quality of your substrate. ECI’s Ion Beam Sputtering coatings are also great for applications that use ultrafast lasers.

Medical Applications

Ion Beam Sputtering coatings are ideal for a variety of medical applications because of increased environmental stability, low loss characteristics, and their ability to meet very strict optical requirements. ECI produces broad band dielectric mirrors using Ion Beam Sputtering for many medical imaging applications. These applications range from scanning mirrors to intra oral mirrors. Some such mirrors are even deposited on the ends of fiber optic assemblies that will be inserted into the human body. ECI can also produce excitation filters, emission filters and dichroic filters for applications that utilize fluorescence microscopy.

LiDAR Applications

Specialized mapping and geographical information systems (GIS) technology are using a specific laser technology known as LiDAR (Light Detection and Ranging). LiDAR is a unique and versatile laser system that actively sends light energy to the ground, allowing for information to be sent back to the sensor regarding surface composition, elevation, etc. LiDAR can also be used for safety features on vehicles, as well as for testing methods for law enforcement officers and traffic safety. Through targeting the transmittance of certain wavelengths, sensors can interpret these readings to analyze speed and proximity to nearby objects. The precision of our IBS coatings make them an ideal match for filters and mirrors used in LiDAR systems.

Please contact us to discuss your IBS coating needs!